HOME > PRODUCTS > > CENTRIFUGAL SEPARATOR FILTER

PRESENTATION

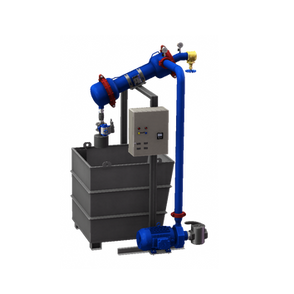

The LAFFI FILTRATION Centrifugal Separator Filters remove by centrifugal action, the solids (grains, fine metal chips, fines and other high density solids), with high efficiency keeping low concentration of solids in tanks and various processes, reducing the accumulation of solids in cooling towers, heat exchangers, chiller and other cooling system equipment.

Performance and quality approved in several market segments.

These units require little or no maintenance, as there are no moving parts that can fail or wear out, or filter elements to clean or replace. The unit requires only a simple automated purge eliminating downtime for cleaning

It meets flow rates of 0.7 ~ 2900 m3 / h with solids retention efficiency of up to 98% for solids above 50µ.

PRINCIPLE OF OPERATION

1. Liquids / Solids enter the unit tangentially to produce a circular flow.

2. Liquids / solids pass through tangential grooves where they are accelerated into the separation chamber.

3. The centrifugal force hurls the heavier particles to the perimeter of the separation chamber, depositing them on the bottom of the unit.

4. The liquid free of solids is kept in the center of the separator by going to the outlet at the top.

5. Clean liquid outlet.

6. Concentrated solids are periodically purged or continuously drained from the separator as needed.

BENEFITS

Do not use filter elements;

No spare parts or moving parts;

No backwash required;

No unproductive stops for cleaning or maintenance;

No need for backup equipment;

Constant pressure loss and flow;

Easy automation for operation;

Compact size, requires small spaces for installation;

System for collecting solids and recovering liquids;

Accessories and devices for concentration of solids for later disposal or recovery;

INSTALLATION OPTIONS

CENTRIFUGAL SEPARATOR FILTER MODELS

PERFORMANCE

PROJECT DATA

Design and manufacture according to ASME VIII - Div I;

NR-13 documentation, when required;

Pressure class: 10 kgf / cm2 - Note: we meet pressure classes of up to 100 KGF / cm2, when required.

CONSTRUCTION MATERIAL

Carbon Steel - ASTM;

Stainless Steel - 304, 316, 316L.

SURFACE FINISH

-

Carbon steel

LAFFI standard paint

Special painting requirements, when required.

-

Stainless Steel

Shot blasting with stainless steel microspheres;

Sanitary polishing when required.

SPECIAL REQUIREMENTS

Several solutions for recovery and collection of solids.

CONNECTIONS

Threaded (Female) - 1 "/2/2.1/2" and 3 "NPT;

ANSI B16.5 flange - 2 "~ 12";

TC - 1 "~ 3";

Vitaulic - When required;

DIN - When required;

SMS - When required.

SEALS

Viton - Buna n - EPDM - PTFE;

Others, when required.

CENTRIFUGAL SEPARATOR FILTER

PHOTO GALLERY

DISCOVER ALL OUR PORTFOLIO

KNOW MORE!

Get in touch with our sales team.